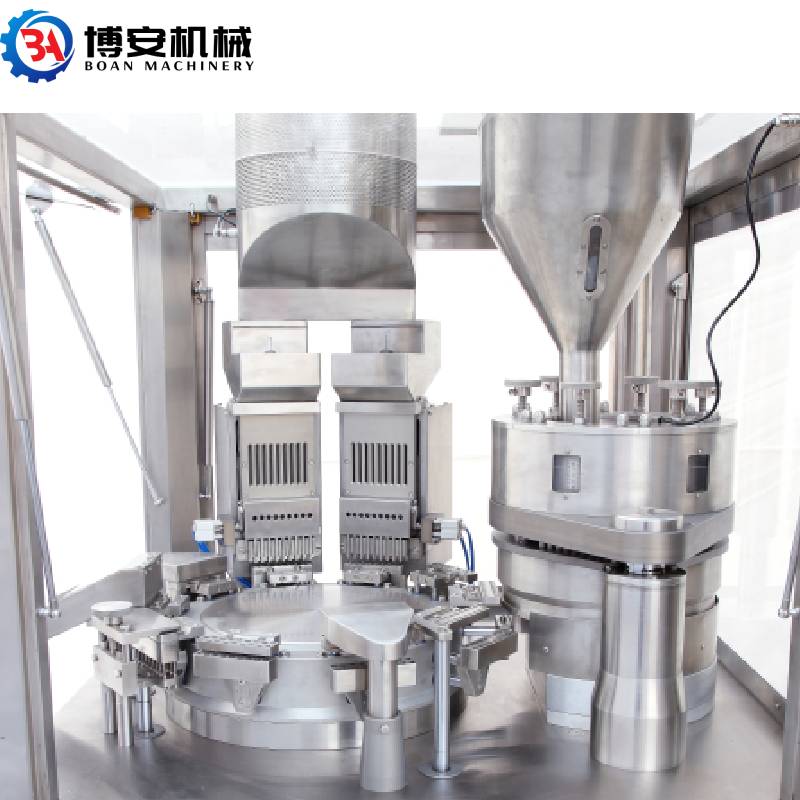

Vous êtes-vous déjà demandé comment les capsules sont remplies avec une telle précision à l'échelle industrielle ? La réponse réside dans une ingénierie de pointe. Ce guide vous présente le flux de travail complet d'une machine de remplissage de capsules — séparation, dosage, fermeture, éjection et contrôle — tout en intégrant des termes clés tels que :capsule taille 00,machine de remplissage de capsules, machine de remplissage automatique de capsules,machine de remplissage de capsules semi-automatique, etmachine de remplissage de capsules manuelle pour faciliter la consultation et la recherche.

Comment fonctionnent les machines de remplissage de capsules

Une remplisseuse de capsules est, en substance, une chaîne de montage miniaturisée conçue spécifiquement pour les capsules. Quelle que soit l'échelle, le processus comprend quatre étapes clés :

Bien que l'ensemble du système soit parfois désigné de manière générale comme unmachine à fabriquer des capsules, le termemachine de remplissage de capsulesdécrit plus précisément le sous-système responsable de l'opération de dosage.

Opérations clés en détail

1. Séparation et orientation des capsules

2. Dosage et remplissage

La méthode dépend de la forme du produit :

3. Fermeture et verrouillage

Une bague de centrage aligne de manière concentrique le capuchon et le corps. Une pression axiale est ensuite appliquée pour verrouiller fermement la rainure.

4. Décharge et assurance qualité en ligne

Les capsules finies sont évacuées par des goulottes. Des trieuses pondérales, des détecteurs de métaux et des systèmes de vision intégrés vérifient automatiquement le poids, l'intégrité physique et l'orientation de l'impression.

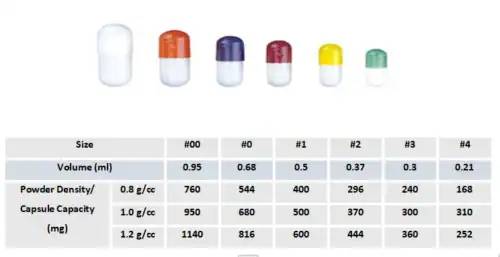

Concentrez-vous sur la capsule de taille 00

Lecapsule taille 00est un élément essentiel dans le développement des compléments alimentaires et des produits pharmaceutiques. Lors du choix d'unmachine à capsules 00oumachine de remplissage de capsules 00, assurez-vous que tous les outils — alésages de plaques segmentées, broches de dosage/tassage et bagues de fermeture — sont compatibles avec letaille de la capsule 00.

Types d'équipement : Trouver le bon équipement

| Taper | Idéal pour | Avantages | Cons |

| Machine de remplissage de capsules manuelle | Recherche et développement, essais pilotes, formation | Faible coût, faible encombrement, fonctionnement simple | Travail exigeant en main-d'œuvre, faible rendement, la régularité dépend des compétences de l'opérateur |

| Machine de remplissage de capsules semi-automatique | Production à petite et moyenne échelle, marques en croissance | Amélioration de la vitesse et de l'uniformité du poids par rapport à la méthode manuelle, réduction de la fatigue de l'opérateur | Ne convient pas à une production en très grand volume ; nécessite une configuration. |

| Machine de remplissage automatique de capsules | Lignes de production à haut volume et multi-références | Débit maximal, excellente uniformité de dose, fonctionnalités BPF/intégrité des données | Investissement initial plus élevé ; nécessite une maintenance assurée par un personnel qualifié |

Coquilles en gélatine vs. coquilles végétales (HPMC)

Les machines modernes peuvent traiter les deux types de coquilles avec des ajustements mineurs :

Ce qui favorise l'efficacité et la qualité

Liste de contrôle de sélection

Choisissez une machine en fonction de vos besoins spécifiques :

Conseils pratiques pour une production stable

Foire aux questions (FAQ)

Q : Une seule machine peut-elle traiter plusieurs tailles de capsules, y compris la taille 00 ?

R: Oui. La plupart des plateformes modernes utilisent des pièces de format interchangeables.machine de remplissage de capsules 00Le kit de conversion comprend généralement une plaque segmentée, des broches de dosage et une bague de fermeture.

Q : Quelle est la différence entre une « machine à remplir les capsules » et une « machine à fabriquer les capsules » ?

A : Techniquement, unmachine à fabriquer des capsulesfabrique elle-même les coquilles vides.machine de remplissage de capsulesLe produit est dosé dans des coques préfabriquées. Ces termes sont souvent utilisés indifféremment dans des contextes plus généraux.

Q : À quelle vitesse peut fonctionner une machine de remplissage automatique de capsules ?

A : Les vitesses varient considérablement. Les machines automatiques d'entrée de gamme produisent des dizaines de milliers de litres par heure. Les modèles à grande vitesse, avec des formulations appropriées et uncapsule taille 00Cette configuration permet d'atteindre des rendements nettement supérieurs.

Q : Puis-je remplir des capsules de liquide ?

R : Oui. Cela nécessite des systèmes spécialisés avec des trémies à température contrôlée et des pompes de précision. L'étanchéité du système de fermeture doit être vérifiée et un cerclage peut être nécessaire pour éviter les fuites.

Jinhai Plaza, No. 21, Jihua 5th Road, Chancheng District, Foshan City, Guangdong Province, China

Jinhai Plaza, No. 21, Jihua 5th Road, Chancheng District, Foshan City, Guangdong Province, China  +0757 82252350

+0757 82252350  +8618613054883

+8618613054883  manager@gdboanmachine.com

manager@gdboanmachine.com