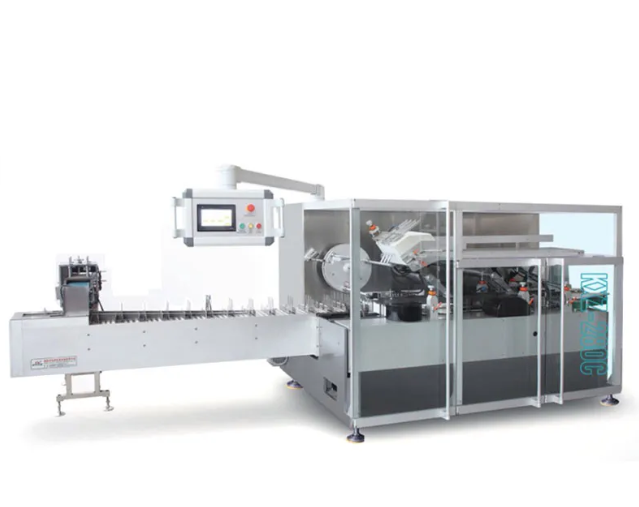

The Boan NovaCarton™ series automatic high-speed cartoning machine is a high-performance packaging solution designed for modern pharmaceutical, healthcare, food, and daily chemical industries. It seamlessly integrates into your production line, intelligently and precisely loading products like bottles, blister packs, tubes, and leaflets into cartons automatically before sealing them. This achieves a fully automated leap from product to finished package. Renowned for its exceptional stability, flexible adaptability, and robust design, the NovaCarton™ has become a reliable partner for enterprises pursuing efficient production and excellent return on investment.

High Speed & Precision, Unleashing Capacity: Utilizing advanced servo-driven and cam-linkage systems, the packaging speed can reach up to 200 cartons per minute. While ensuring high-speed operation, it achieves millimeter-precise alignment and insertion of products into cartons, maximizing your production line output.

Flexible Adaptation & Easy Changeover: Modular design provides outstanding flexibility. The standard carton size range is extensive (Length: 100-250mm × Width: 60-130mm × Height: 20-70mm) and can be customized for your specific box styles. Quick size-changeover capabilities perfectly suit multi-variety production needs.

Rock-Solid, Stable Operation: The entire machine employs high-strength steel structure and precision-engineered components, weighing 3000 kilograms. This provides a solid foundation for long-term, high-load continuous operation, effectively reducing vibration and wear to ensure persistent and stable production.

Intelligent Control & Simple Operation: Equipped with a large color touchscreen HMI (Human-Machine Interface), it intuitively displays production speed, counts, and operational status. An intelligent fault diagnosis system provides instant alarms and maintenance prompts, significantly reducing operational difficulty and downtime.

Robust, Durable & Easy Maintenance: Key moving parts use high-quality branded components for long service life and high reliability. The design emphasizes maintenance convenience, with many modules allowing for quick disassembly, facilitating cleaning and upkeep to keep the equipment in optimal condition.

| Item | Parameter / Description |

|---|---|

| Model | Boan NovaCarton™ BN-280C (Custom models acceptable) |

| Cartoning Speed | 100 - 200 cartons/min (Depending on product & carton specifications) |

| Applicable Carton | Basis Weight Range: 250 - 450 g/m² (e.g., E-flute corrugated, cardboard) |

| Carton Size Range (L×W×H) | (100-250)mm × (60-130)mm × (20-70)mm (Customization supported) |

| Power Supply | 380V / 50Hz / Three-phase |

| Total Power | 1.5KW |

| Air Source Requirement | Working Pressure ≥ 0.6 MPa, Consumption ~ 20 m³/h (Requires clean, dry air) |

| Machine Dimensions (L×W×H) | Approx. 5600 × 1800 × 1900 mm |

| Net Weight | Approx. 3000 KG |

Automatic Carton Feeding & Forming: Vacuum suckers smoothly pick up pre-folded flat cartons and open them precisely, ready for product loading.

Automatic Product Infeed: Products like bottles or blister packs, along with leaflets (if required), are fed automatically and neatly into the opened cartons via conveyor belts or guide channels.

Tuck Flaps & Reliable Sealing: Precision mechanisms sequentially fold the left and right inner flaps of the carton and securely close the lid via tuck-in or glue sealing.

Finished Product Outfeed: The perfectly sealed cartons are discharged steadily and can be easily connected to downstream equipment like coders, labelers, or case packers to form a complete automated packaging line.

The Boan NovaCarton™ high-speed cartoner is an ideal choice for large-scale production in the following fields:

Pharmaceuticals & Healthcare: Automatic cartoning of vials, oral liquid bottles, blister packs, and softgel bottles.

Food & Beverage: Packaging for condiment bottles, snack bags, tea boxes, and premium food gift boxes.

Daily Chemicals: Final cartoning of cosmetic jars/bottles, toothpaste, soap, and detergent bottles.

Other Industrial Goods: Small electronics, parts, and other items requiring box packaging.

We are committed to providing high-value equipment solutions for our customers.

Focus on Engineering & Manufacturing: Deeply rooted in the field of automated packaging machinery, we win market trust through solid craftsmanship and reliable quality.

Customization Capability: We understand that standard solutions don't fit all. We offer practical adjustments and customizations based on your specific products and plant conditions.

Full-Cycle Service: We accompany you throughout the entire process—from solution communication, installation, commissioning, and operator training to timely after-sales support—ensuring your equipment runs efficiently.

Excellent Cost-Effectiveness: We provide equipment that offers the best balance between performance, durability, and price, making it a wise choice for improving production efficiency and controlling investment costs.

Take Action Now to Upgrade Your Packaging Productivity!

Contact the Boan Machinery Team to obtain detailed technical documentation, success case videos, or to schedule an on-site machine trial. Our engineers look forward to providing you with professional packaging solutions.

Boan Machinery — Solid, Efficient, Packaging the Future.