Rotary tablet presses are the backbone of solid-dosage manufacturing, enabling high-volume, consistent production of pharmaceutical tablets, nutraceuticals, and other compressed products. Whether you're scaling up production or selecting new equipment, understanding the working principles, core advantages, and key purchasing considerations of tablet press machine is crucial for improving production efficiency and compliance. This guide integrates technical insights with a practical buying checklist to help you fully understand equipment such as tablet press, pill maker machine, and pill pressing machine, and make informed decisions.

How Rotary Tablet Presses Work

Rotary tablet presses convert powdered or granular raw materials into uniform tablets through a continuous automated process, with a core workflow consisting of four coordinated stages:

Filling: Raw materials are fed from a hopper into a feeding system, which evenly distributes them into the die cavities on a rotating turret.

Metering: The feeder ensures a consistent powder volume in each die cavity, laying the foundation for uniform tablet weight.

Compression: As the turret rotates, each die cavity passes through pre-compression and main compression stages. Pre-compression removes air pockets, while main compression applies high pressure (hundreds of kilonewtons) to fuse the powder into dense tablets.

Ejection: An ejection cam lifts the lower punch, pushing the formed tablet out of the die cavity, which is then collected via a chute or take-off blade.

This continuous cycle allows modern tablet press machine to achieve a production capacity of hundreds of thousands to over one million tablets per hour, far exceeding that of single-punch tablet presses. Both tablet press and pill pressing machine are designed around the core working logic of "continuous forming" to ensure production efficiency.

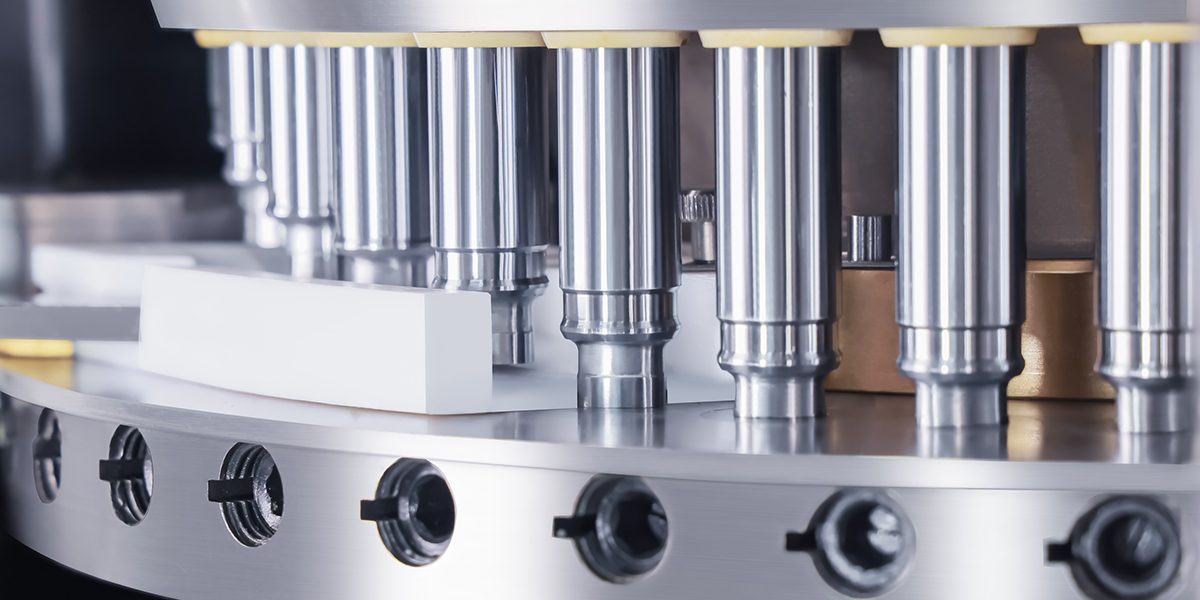

The performance and reliability of tablet press machine depend on the coordinated operation of precision-engineered components. Both pill maker machine and tablet press machine share a highly consistent core component structure:

Hopper & Feeder: Stores powder and uniformly feeds it into die cavities. Advanced feeders are equipped with paddles or agitators to prevent material bridging and ensure stable feeding.

Punches & Dies: Dies are hardened steel cavities that define the shape and size of tablets, while upper and lower punches apply compression force. Micron-level tolerance control is critical for ensuring consistent tablet weight and dimensions.

Turret: A circular rotating platform that carries multiple punch/die sets. The number of stations (10–40+) directly affects production capacity—the more stations, the higher the output.

Cam Tracks & Rollers: Guide punches through processes such as filling, compression, and ejection in sequence, achieving precise timing and pressure control.

Drive System: Composed of motors, gearboxes, and variable-frequency drives, it provides power to the turret and allows adjustable production speeds.

Control Panel & Sensors: Controls parameters such as turret speed and compression force via PLC/touchscreen. Sensors real-time monitor pressure and detect faults to ensure process stability.

Machine Types & Configurations for Diverse Needs

tablet press machine offers a variety of specialized configurations to meet different production needs, while deriving segmented models such as tablet press and pill tablet press:

Multi-Station Rotary Tablet Press: The standard model for large-scale production, equipped with multiple punch/die sets and high capacity, it is the mainstream type of tablet press machine.

Bi-Layer/Tri-Layer Tablet Press: Adopts stacked hoppers and dies to produce multi-layer tablets (e.g., controlled-release drugs with different formulations), adapting to the complex forming needs of pill tablet press.

High-Speed Rotary Tablet Press: Designed specifically for ultra-high production capacity (up to over 1 million tablets per hour), it features advanced automation and lubrication systems, making it the preferred tablet press type for large pharmaceutical companies.

Dry-Coating (Tab-In-Tab) Tablet Press: Produces "tablet-within-a-tablet" structures through dual feeders and specialized molds to achieve targeted drug release, belonging to the high-end configuration of tablet press machine.

Containment Tablet Press: Designed for potent APIs, it uses an enclosed system to prevent contamination and ensure operator safety, suitable for high-demand pill pressing machine application scenarios.

Rotary tablet presses have become the preferred choice for industrial production due to their comprehensive advantages in speed, quality, and efficiency. Whether tablet press, pill maker machine, or pill tablet press machine, they all offer the following core highlights:

High Throughput: With a production capacity of 250,000 to over 1 million tablets per hour, it can shorten production cycles and reduce costs during large-scale production, far exceeding the small-batch production capacity of ordinary pill maker machine.

Uniform Quality: Consistent compression conditions across all stations ensure uniform tablet weight, hardness, and thickness—critical for pharmaceutical dosage accuracy and a core requirement for pill tablet press.

Automation & Efficiency: Fully automated operation reduces labor input and human error, with features such as automatic feeding, automatic lubrication, and automatic parameter adjustment. Both pill pressing machine and tablet press support continuous operation.

Scalability: Easily adapt to growing production capacity needs by adding turret stations or upgrading to larger models, suitable for the large-scale upgrading scenarios of tablet press machine.

Versatility: Changing molds allows production of tablets of different shapes, sizes, and formulations (e.g., chewable tablets, effervescent tablets, multi-layer tablets), compatible with the diverse production needs of pill tablet press machine.

Compliance: Enclosed design, stainless steel materials, and data traceability functions can meet GMP, EU GMP Annex 11, and FDA 21 CFR Part 11 requirements, making it an essential condition for tablet press to enter the pharmaceutical industry.

To avoid losses caused by procurement mistakes, prioritize the following four factors when selecting equipment such as tablet press machine and pill pressing machine:

1. Current Good Manufacturing Practice (cGMP) Compliance

Non-compliant equipment may lead to contamination, product recalls, and regulatory penalties. Both pill tablet press machine and tablet press must ensure compliance with cGMP standards through the following designs:

Stainless Steel Material: Structural components (frames, casings) use SS 304, while drug-contact surfaces (hoppers, punches, dies) use SS 316 to prevent contamination.

Hygienic Design: Large-platform structure with rounded corners, equipped with powder recovery systems and built-in dust collectors to reduce the risk of cross-contamination.

Data Integrity & Traceability: Features access control, audit trails, and electronic signatures to record production parameters and ensure accountability.

2. Tablet Weight Uniformity

Precise pharmaceutical dosage is crucial. pill maker machine and pill tablet press should focus on the following characteristics:

Precision Tooling: Strict tolerance control of punches and dies to ensure consistent die cavity volume.

High-Efficiency Forced Feeder: Actively feeds powder into die cavities to eliminate air gaps and uneven density.

Real-Time Monitoring: Equipped with pressure deviation detection, automatic fill depth adjustment, and non-conforming tablet rejection functions.

3. Production Capacity & Downtime Control

When purchasing tablet press machine, do not only focus on theoretical capacity. pill pressing machine also needs to consider actual production constraints and efficiency-enhancing designs:

Theoretical vs. Actual Capacity: Test the equipment with your own raw materials, fully considering the impact of powder flowability, tablet design, and mold change time.

Downtime-Reducing Designs: Digital recipe management (one-click parameter recall), modular quick-release components, and standardized molds for fast product changeover.

Preventive Maintenance: Regularly inspect wearing parts (punches, dies, compression rolls) to avoid sudden failures.

4. Safety & Environmental Compliance

Both tablet press and pill tablet press machine need to ensure workshop safety and sustainable production through the following designs:

Operator Safety: Interlocked safety doors, emergency stop buttons, and safety monitoring systems for detecting pressure overload, vibration, or motor faults.

Tool-Free Mold Change: Precision machining design supports fast and safe replacement of dies and punches without special tools (e.g., HGZP-17D model mold change takes only 30 minutes).

Environmental Friendliness: Equipped with acoustic enclosures and damping elements for noise control; adopts servo motors to save 15–35% energy; intelligent lubrication systems reduce pollution and waste.

Maintenance & Cleaning Best Practices

To extend the service life of equipment such as tablet press machine and pill maker machine and ensure compliant production, follow these maintenance specifications:

Daily Cleaning: Disassemble and clean drug-contact parts (hoppers, punches, dies) using pharmaceutical-grade solvents to remove residual powder.

Regular Inspection: Check the wear of turret bearings, cams, and gearboxes, and lubricate moving parts according to the manufacturer's requirements.

Part Replacement: Regularly replace worn punches and dies to maintain tablet quality.

Calibration & Validation: Regularly calibrate the filling and compression systems to ensure compliance with GMP standards.

Frequently Asked Questions (FAQs) About Rotary Tablet Presses

1. What is the difference between a rotary tablet press and a single-punch tablet press?

Rotary tablet presses achieve continuous large-scale production (thousands of tablets per minute) through multiple punch/die sets on a turret, while single-punch tablet presses produce one tablet per cycle, suitable for R&D or small-batch production. tablet press machine offers better uniformity and scalability but requires higher initial investment, while pill maker machine is mostly small-batch models, with application scenarios similar to single-punch tablet presses.

2. How to ensure that tablet press complies with GMP standards?

Select equipment with SS 316 drug-contact surfaces, hygienic design (no sharp corners/gaps), data integrity functions (audit trails, electronic signatures), and easy cleaning. Conduct regular validation and calibration to maintain compliance—this requirement also applies to pill tablet press machine.

3. Can pill pressing machine produce multi-layer or complex-structured tablets?

Yes—bi-layer/tri-layer tablet presses produce multi-formulation tablets through stacked hoppers, while dry-coating tablet presses can produce "tablet-within-a-tablet" structures for targeted release. Some high-end pill pressing machine also support similar complex forming needs.

4. What factors affect the production capacity of tablet press machine?

Core factors include turret speed, number of stations, powder flowability, tablet size/thickness, and mold change time. Test the equipment with your own raw materials to determine the actual capacity—the factors affecting the capacity of pill tablet press are consistent with this.

5. How to maintain the tablet weight uniformity of pill maker machine?

Use precision tooling and high-efficiency forced feeders, and equip with real-time monitoring systems. Regularly inspect and replace worn punches/dies to ensure stable powder feeding—this method is also applicable to all types of tablet press.

6. What safety features should be considered when purchasing pill tablet press machine?

Key safety features include interlocked safety doors, emergency stop buttons, vibration/pressure monitoring functions, and tool-free mold change design to reduce operational risks—the safety selection standards for pill pressing machine are the same.

7. How to reduce the downtime of tablet press machine?

Select equipment with digital recipe management, modular quick-release components, and standardized molds. Formulate a preventive maintenance plan to handle parts before they wear out—this solution is also applicable to tablet press and pill maker machine.

8. What manufacturing materials are used in pill tablet press?

Structural components use SS 304 (cost-effective, corrosion-resistant), while drug-contact surfaces use SS 316 (stronger corrosion resistance, suitable for active ingredients). High-strength components such as turrets may use SS 2Cr13, consistent with the material standards of tablet press machine.

Jinhai Plaza, No. 21, Jihua 5th Road, Chancheng District, Foshan City, Guangdong Province, China

Jinhai Plaza, No. 21, Jihua 5th Road, Chancheng District, Foshan City, Guangdong Province, China  +0757 82252350

+0757 82252350  +8618613054883

+8618613054883  manager@gdboanmachine.com

manager@gdboanmachine.com